Services

Home - Services

Industries

LS Plastech serves

We provide solutions to a varied set of industries. With supply chain expertise & industry partners there is no limit to what we can do.

Packaging

Consumer Goods

Automotive

Telecommunications

Appliances

Electronics

Services

Because you are not looking for processes, you are looking for solutions

LS PLASTECH offers a fully-fledged service by becoming a one-step shop for your plastic manufacturing needs through in-house processes and business partnerships.

Program Management

Program Management

Mold Design & Build

Mold Design & Build

Plastic Injection Molding

Plastic Injection Molding

Decoration

Decoration

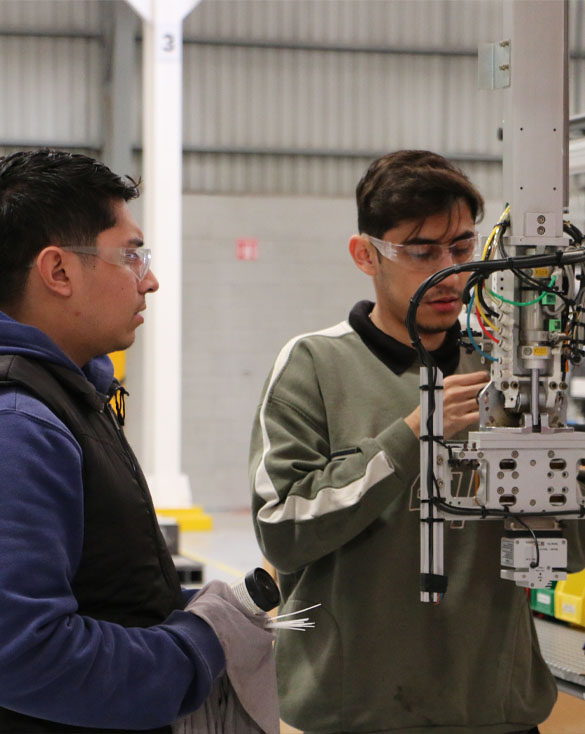

Integrated Assembly

Integrated Assembly

Packaging & Logistics

Packaging & Logistics

Why choose us

Your Mexican Manufacturing Partner

Whether you are seeking to nearshore, relocate, reduce supply chain complexity or simply want a better supplier our competitive advantages and ease of doing business set us apart from and make working with LS Plastech the obvious choice for contract manufacturing.

Project Development

From Idea to Reality with the end customer in mind.

Business Partnership

We strive to help world-class customers succeed.

Investment Capacity Available

Aligned with projects and client demands.

Program Management

Our experienced staff will lead your projects launch.

Quality First

We are an ISO 9001:2015 Certified Company.

Strategic Location

Inside an Industrial Zone 1 Hour Away From US Border.

Value Added Processes

For higher quality end products.

Top Tier Customer Service

Constant communication and follow up.

Continuous Improvement

We adopt leading practices and seek to be better in all that we do.

Lean Philosophy

Low overhead leads to low costs.